|

Overview of Process1. Hairpin Press Forming It is a process of multi-forming of square coil that is rolled in the bobbin in the shape of hairpin after linearizing, shedding and cutting at the fixed length. Hairpin is a three-dimensional form with U, V and R. Three-dimensional forms are formed through CAM driving or individual Servo driving by using each mold.

|

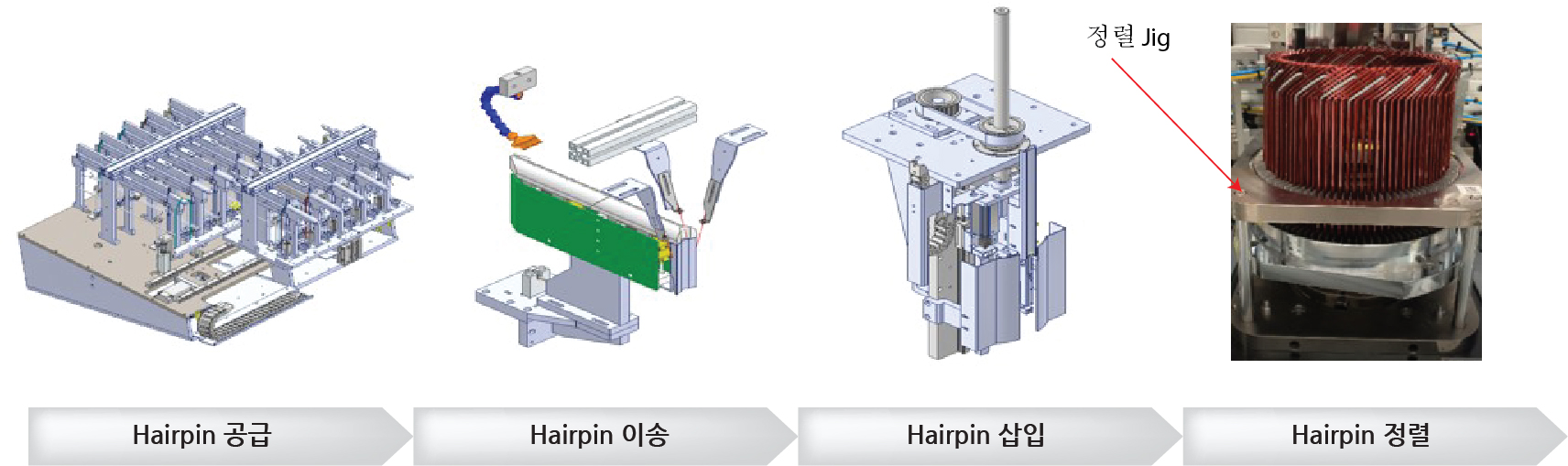

2. Hairpin Alignment

Hairpin supplied to Cassette is inserted and aligned to jig one by one by using polyarticular robot. 1-2 layers or 1-3 layers are aligned in order according to the fixed alignment orders. It is normal to use robot method when inserting hairpin into the jig, and there are also ways to directly insert free dropped hairpin in the jig or to use chain or planet gear.

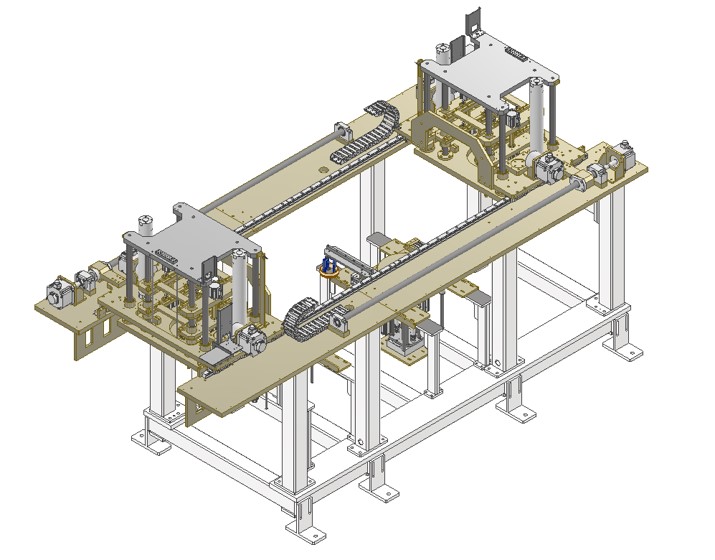

3. Pre-Inserting

When jig with aligned hairpin is supplied, disassemble entire hairpin from aligned jig while keeping its shape by using pipe expanding jig and pre-insert to input stator core. Full insertion is made right before twisting which is a next process.

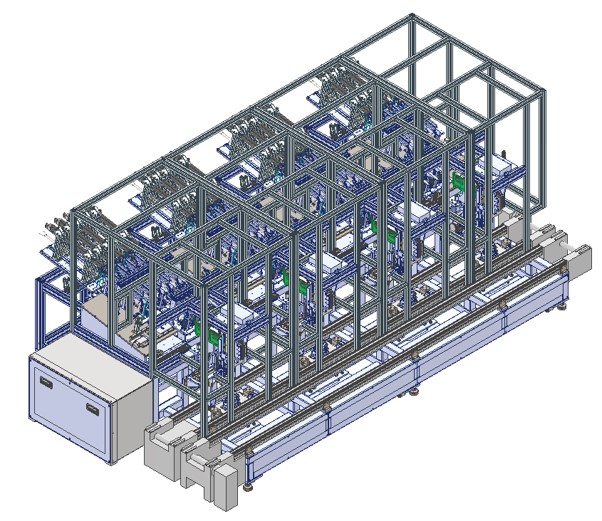

Press Forming Machine

Aligner

Pre-inserter

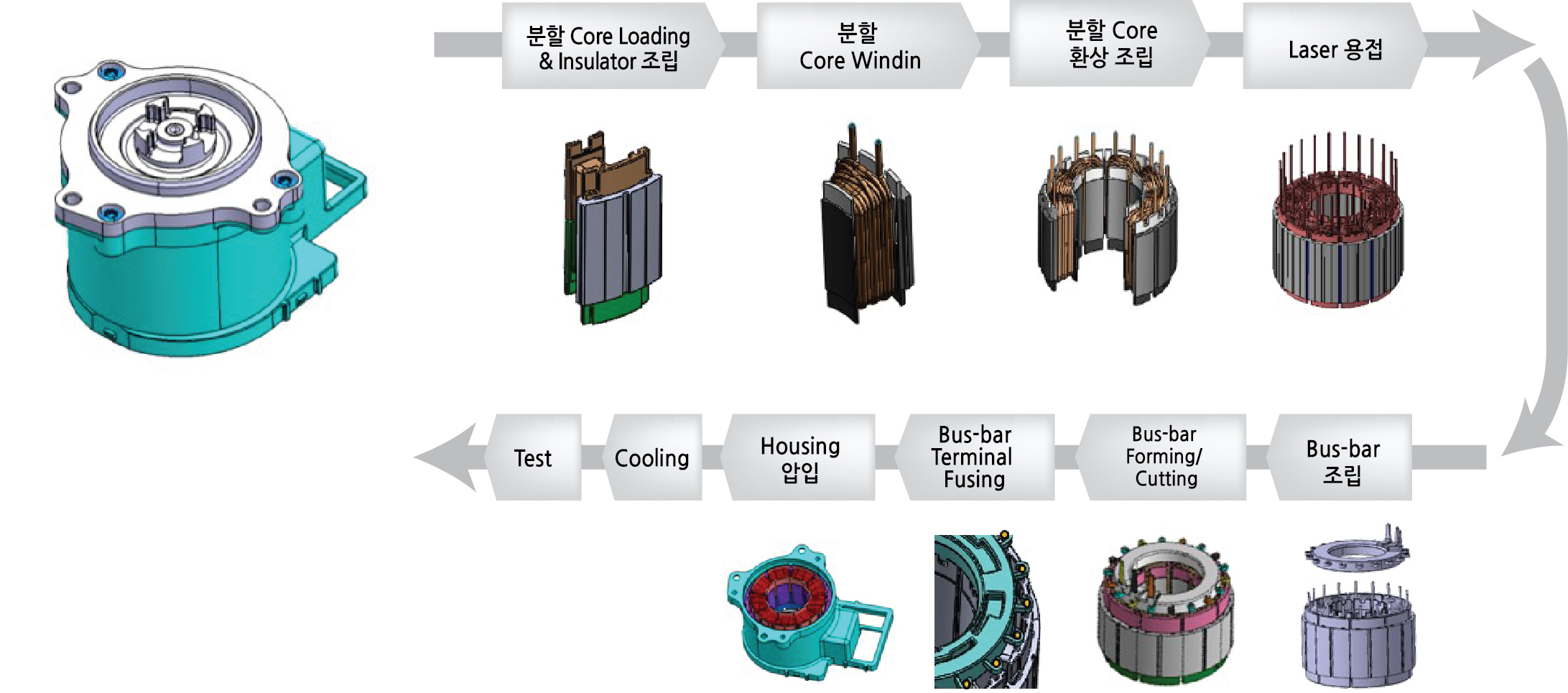

Small-sized precise motor is used in various motor elements as automobiles advance. EPS, ABS and Wafer driven motor are representative ones. The company is manufacturing and supplying stator manufacturing line of such small motor based on the technology of coil winding.

Split core is assembled into 9 splits and 12 splits to form stator core for the efficiency of motor. Winding axis is increasing in the split core to improve productivity of coil winding and reduce investment cost of winding machine. The company is already manufactured and supplied 3-axis and 4-axis winding machine, and has developed 6-axis winding machine in 2020.

|

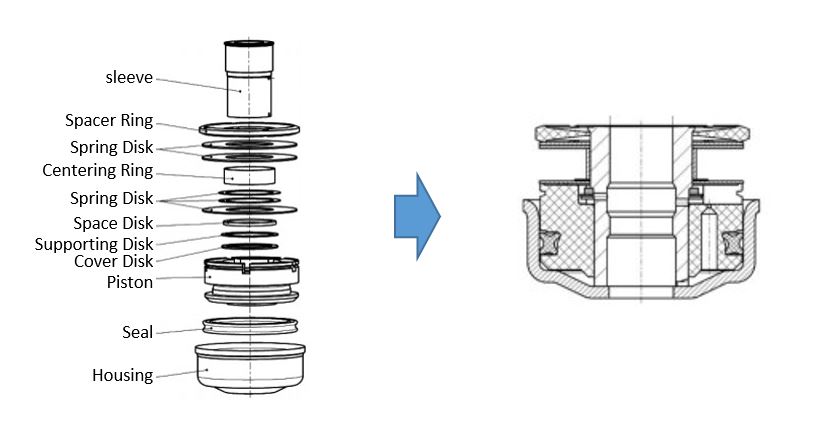

Overview of equipmentWe mainly manufacture equipment that automatically assembles damping control valves, which are core of components of automobile shock-absorber. There is stand-alone type that assembles only part of parts and a line that automatically assembles the entire value. It is equipment that precisely assembles parts that were passed after feeding and measuring size of each part of valve through align, press fitting, etc.

|